High-Level Project Summary

Our project consists of a pair of latches and a motorized casing retraction system that can either allow the latches to separate or lock them in place. It solves the problem by vectoring the force caused by the reefing line, away from the release mechanism itself, requiring less force to release the reefing line. Because it requires less force, a simple dc motor can be used instead of explosives. Our design also doesn’t release debris when operated. Our model also only uses one type of metal (stainless steel), almost eliminating degradation because of galvanic corrosion.

Link to Project "Demo"

Link to Final Project

Detailed Project Description

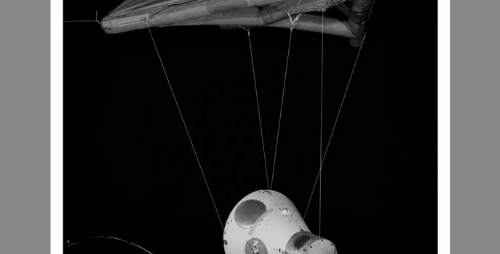

Our device attempts to detach the ends of a parachute reefing line, allowing the parachute to reach its maximum deployment radius. To achieve this, the ends of the reefing line will have identical latches that are rotated 180° degrees from one another. Because of the slanted design of the latches, the tension of the line would cause them to come apart very easily. The retractable casing is meant to stop the latches from coming apart while they’re inside it. The slanted surface of the latches causes the force from the line to be vectored into a net expansion of the internal latch system, not allowing the assembly to come apart. When the reefing line is meant to detach, a couple of motorized, vulcanized rubber rollers, pull the ribbed casing into their housing, while its geometry prevents the latches from entering it. The reefing line is meant to run through the roller housing using the line tension as its mounting solution. All the metallic materials are stainless steel to prevent corrosion in the system in the long run. Since everything is self-contained and re deployable, it is expected to last multiple redeployment cycles, without the need to use consumables.

During the development of this project, we tried to use collaborative tools to facilitate the iterative process. We used Google Jamboard for sketches and GrabCAD for file sharing. The CAD software used was Autodesk Inventor because of its integrated tools such as integrated rendering, and assemblies. Our design could be easily fitted with many different activation solutions, such as a simple timing circuit or a more complex one like an altimeter.

Space Agency Data

We base our project on sources provided by NASA and International Space Agencies. We were able to analyze the evolution of parachute mechanisms, how they were used in Past Missions, what were the successes and errors when using them, and see how we could improve and propose the best possible version.

The locks we use are based on Mechanical Release Systems, which allows the rope to be released efficiently and quickly. Thanks to the videos provided, we were also able to analyze the tension forces and how the elements of the mechanism are affected by the stress of take-off and landing.

Hackathon Journey

We started to break up the challenge to the most basic elements possible, we were able to see what actions we needed to perform for the parachute to open. By watching videos and reading articles provided by NASA we realized that we could open the parachute by separating two pieces of metal through a system of gears.

Then, we started to troubleshoot problems like “How are we going to reduce the amount of play in our system and reduce the number of unwanted forces?”, or “How are we going to make it so our system will work even if it’s moving very aggressively? (since it's attached on what’s essentially a string)” by polishing our design and trying to see if one of the problems actually could help us solve others (For instance, the fact that the box is mounted on a string, we realized that the tension of it was a good inner support fo the box).

Most of the integrants of our team were already on a robotics team together, and share a good idea on how mechanical systems work and at the same time eager to tackle an actual problem that happens in today’s aerospace missions.

We learned a lot during this competition, from the technical to the social. By working from home during these hard times, we all needed a way to let our creativity, knowledge, and the craving for more of it out, and this competition not only gave us all of those things but also allowed us to know more about each team member and have a good time while doing what we love.

References

- Mircea Badescu, Xiaoqi Bao, and Yoseph Bar-Cohen. (2014). Shape memory alloy (SMA)-based launch lock. october 02nd, 2021, de NASA Website: https://trs.jpl.nasa.gov/bitstream/handle/2014/45484/14-0701_A1b.pdf?sequence=1

- Adam Sexton, Chris Dayton, Ron Wendland and Joseph Pellicciotti. (2011). DESIGN, DEVELOPMENT AND TESTING OF THE GMI LAUNCH LOCKS. october 02nd, 2021, de NASA Website: https://ntrs.nasa.gov/api/citations/20110016488/downloads/20110016488.pdf

- Robert Goodwin. (2011). APOLLO SPACECRAFT NEWS REFERENCE. october 2nd, 2021, de NASA Website: https://www.hq.nasa.gov/alsj/CSM_News_Reference_H_Missions.pdf

- Jennifer Stanfield. (2010). The Root of the Problem: What Caused the Ares I-X Parachute to Fail?. october 02nd, 2021, de NASA Website: https://www.nasa.gov/mission_pages/constellation/ares/parachute_results.html

- NASA Technology Transfer program. (2020). Separation Device Launches New Science Payloads. october 02nd, 2021, de NASA Website: https://spinoff.nasa.gov/Spinoff2020/ip_8.html

Tags

#Hardware #SpaceMissions #ReefingLine #Future #NASA # Innovation

Global Judging

This project has been submitted for consideration during the Judging process.