High-Level Project Summary

The project is a mechanical device for the smooth separation of two components, with operation in microgravity decoupling, as example a cubesat launched in space. The idea has been studied and taken forward in this “Let it go” challenge was to design cylindrical parts, which would be fitted together, which would allow the separation to be the elastic deformation of the material used in the outer cylinder, thus releasing the cylinder attached to the uncoupled component, the inner cylinder would deform only after a clamp is displaced. The reasons for the team to think about this solution were the device's reuse, no space junk production and the size reduced to an AAA battery.

Link to Project "Demo"

Link to Final Project

Detailed Project Description

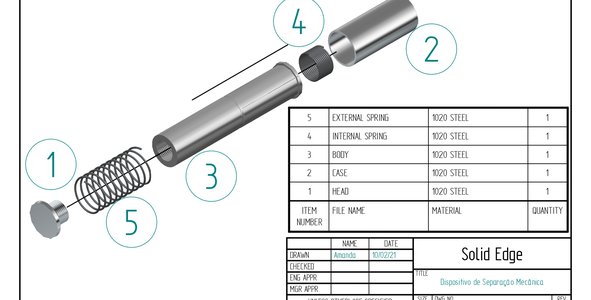

The Decoupling Mechanical Separation Device project, developed by the Supernova team, basically consists of two main parts, which are an external cylinder equipped with a cavity to put in the internal cylinder, which in turn will be the part to be uncoupled. The external cylinder will have radial cuts to facilitate's deformation.

Order for the two parts to be perfectly locked and to prevent deformation from occurring, a third cylinder was inserted in the system that guarantees this function of embracing the external cylinder.

to ensure that the clamp remains in place a spring system has been proposed

The clamp cannot be detached from the device in order not to generate space debris, so the way the team chose to keep it in place was by protrusions at the limits of its movement, but this created the problem of inserting it in the external cylinder, for this reason it was decided to make a screw head on one side of the project.

The material chosen to make the device was 1020 steel, The region subject to the greatest attraction is the part where the internal spring with the chamfer is located, in which a cross-sectional area of 17.52 mm2 was calculated, with the yield limit of the steel being 350 MPa (necessary traction to start having plastic deformation), and having an angle of 45 degrees, an approximate capacity to withstand 12,264 N of force in the sense of disconnecting the two parts was obtained.

The mass calculated by the software used in the technical drawing and in the 3d model was 0.014 kg and a volume of 0.00173 m3.

To perform the decoupling, the clamp needs to be retracted, several ways how NASA can trigger this device were proposed by the team, such as using electromagnetism, super elastic materials with memory, hydraulics and thermal expansion.

Internal cylinder that will be uncoupled:

Technical drawing

Space Agency Data

The data that NASA made available through articles, websites and videos was essential in the 2021 hackathon journey, as it gave us an explanation and inspiration throughout the process.

The main thing was to show us the importance of not creating space junk, occupying little space, being resistant and precise. The examples given were inspiring such as the use of super elastic material with memory and the breaking of the screw. All the information that NASA gave to the team was extremely relevant during the development of the project.

Hackathon Journey

The entire experience with the Nasa Space Apps Challenge was extremely beneficial for all five members of the team, in it we were able to get a sense of the difficulties of working in the aerospace area, the type of innovations that are necessary to carry out a mission with accurately and safely, the importance of research and creativity in this process and also the development of good teamwork during the process.

References

National Aeronautics and Space Administration. Nasa Space Apps Challenge, 2021. Available in: https://2021.spaceappschallenge.org/challenges/statements/let-it-go-without-a-bang/resources. Access: October 02, 2021.

Tags

#nasa, #spaceappschallenge, #mecanicalseparation, #UTFPR, #PontaGrossa, Brazil

Global Judging

This project has been submitted for consideration during the Judging process.